Cart

There are 0 product(s) in your cart

Mounting – Which possibilities offers ABES ?

Overview of the Mounting-types

Here you find an overview of all the mounting types of our products.| Concrete embedment | Concrete embedment with Ground Shells | Screw on | |||||||||

| Stationary (not removable) |

Removable | Ground level or beneath | |||||||||

| Fixed installation | 3p-Technologie | 3p-Hoch | 3p-Snaplock | Universal Ground shell |

ABES - Groundshells for single Bicycle-Stands |

3p-Multi-Flange | Screw on with Flange | Fold-down | ABES Trapezoidal Rails |

||

|

|

|

Bicycle Stand 450 & 451 |

Bicycle-Stand 453 LED |

|

Rail systems 452 450-1, 473, 480 |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

| learn more | learn more | learn more | learn more | learn more | learn more | learn more | learn more | learn more | learn more | ||

-

3p-Technology

-

3p-Technology with ground shell and predetermined breaking point

In 2001, ABES has introduced 3p-Technology, a fastening system that allows the fast repair of an impacted bollard in just a few steps.

The core of 3p-Technology is a junction piece with a predetermined breaking point. When an external force is exerted on it by a vehicle, the connector yields and breaks at its predetermined breaking point. Except for possible scratches on the bollard, all the parts, including the foundation and the paving, remain undamaged. The junction piece is exchanged, and in only a few minutes the bollard is ready again – without losing any of its stability.

In countless cities and municipal institutions, 3p-Technology has become the standard fastening system.

On request, all bollards, LED lighting bollards, and ashtray bollards as well as miscellaneous waste containers and benches can be supplied with 3p-Technology. Together with a junction piece, the bollards are placed in a ground shell (100 mm, 300 mm, 500 mm) and connected firmly and without clearance to one another with a clamping cone and screw set. Either hexagonal, triangular or ABES special head screws can be used.

view 3p-Technology

Cost comparison

view 3p-Technology

Cost comparison

Products with this Mounting Type:

Back to the overview. -

-

3p-High

-

3p-High with ground shell and predetermined breaking point

In the "3p-High" variant, the screw connection on the bollard is higher than in the standard version. It is primarily intended for use with the fire department triangular key (DIN 3223) with a long handle. In this way, the lever travel is extended downwards, which enables the screw connection to be opened and closed without setting the tool down.

This design can significantly speed up the removal of the bollards, especially for fire brigade and rescue service operations, where time is a critical factor.

Products with this Mounting Type:

Back to the overview. -

-

3p-Snaplock

-

3p-Snaplock with hybrid ground shell

Self-latching fastening system for bollards.

Fast setup in the ground shell; convenient removal without having to bend down.

On request, many bollards can be supplied with a self-latching lock. It is unlocked either by means of a triangular or cylinder lock. The cylinder lock can be provided by the customer as long as the minimum and maximum dimensions are observed.

ADVANTAGES:

Customers using a specific ABES model, made for example of cast aluminium and with an emblem, can continue to use this bollard form even when, instead of a predetermined breaking point, a snaplock is requested.

The ground shells for 3p-Snaplock and 3p-Technology are identical. They can therefore be used selectively and alternatively.

Videos

-

-

3p-Multiflange

-

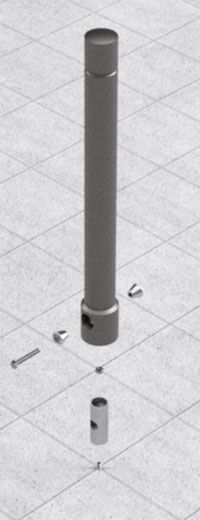

3p-Multiflange without ground shell

To screw on without ground shell, with predetermined breaking point.

Befestigungssystem, mit dem Absperrpfosten mittels eines Verbindungszylinders auf einem Punktfundament verschraubt werden.

DESCRIPTION:

Fastening system where the bollards are screwed to a pad foundation by means of a connecting cylinder. After the creation of a pad foundation, a threaded sleeve is embedded then anchored in the foundation by adding the appropriate kind of injection mortar. The connecting cylinder is then screwed onto the threaded sleeve with an M12 hexagonal screw.

After these preparations, the bollard is pinned on the connecting cylinder. The openings on both sides are brought into line.

Finally, the bollard and the connecting cylinder are firmly (non-positively and positively) connected to each other by means of clamping cones and a screw (hexagonal, drop shape or triangular screw).

The plate, having a cross shaped cut on its underside, purposefully yields after a force is exerted on the bollard and before major damage occurs.

All barrier posts or bollards suited for the standard 3p-Technology can be used.

ADVANTAGES:

- The screws of the connecting cylinder on the threaded sleeve are on the inside and are neither visible nor directly accessible from the outside.

- Low installation costs: pad foundation instead of a deep foundation for a ground shell.

- Low repair costs after impact:

-

- . Affordable and quick exchange of the connecting cylinder.s

- ∙ Generally, the paving will not get damaged.

- ∙ The bollard can be reused.

- Bollards, clamping cones, and screws are 100 % compatible with 3p-Technology.

- Storage costs are low and manageable.

Video

-

-

Stationary

-

Most of the items from the ABES product range can be set in concrete. Their removal is then no longer possible. The following items cannot be set in concrete: LED bollards, Lean-on Bench 108, Bench 100, 103, 104, 141, 142 et al.

Most of the items from the ABES product range can be set in concrete. Their removal is then no longer possible. The following items cannot be set in concrete: LED bollards, Lean-on Bench 108, Bench 100, 103, 104, 141, 142 et al.

-

-

Flange for screwing

-

Aboveground or underground

For some products, circumferentially welded-on rings or flanges are either required by their design or requested by the customer. Anchor screws are used to fasten these products to a solid surface.

This fastening can either be executed aboveground at +/- 0 mm or underground, e.g. at -100 mm. The advantages of an underground fastening are that a paving can be added subsequently and that the screw connection is covered.

Products with this Mounting Type:

Back to the overview. -

-

Collapsible bollards and barriers

-

Another fastening variant are bollards and parking barriers that can be folded to clear an entrance or a parking spot.

Another fastening variant are bollards and parking barriers that can be folded to clear an entrance or a parking spot.

The bollards are laid in a recess or on the ground by means of a tilt mechanism or a hinge. The advantage of a recess is that the bollard cannot be damaged when it is folded down at ground level. There is no tripping hazard and driving over is possible without difficulties.

-

-

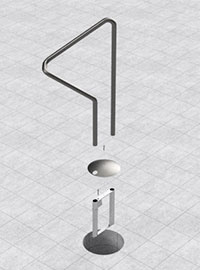

Removable bicycle stands and racks

-

For some of our bicycle stands and racks we offer specific ground shell systems that allow their removal at any time.

For some of our bicycle stands and racks we offer specific ground shell systems that allow their removal at any time.

- BicycleStand 450-1 and 450-2:

Ground shell f. Bicycle-Stands - BicycleStand 453 and 453 LED

Ground shell f. Bicycle-Stands

- BicycleStand 450-1 and 450-2:

Products with this Mounting Type:

Back to the overview. -

-

Removable with ground shells for Ø 48, 60 und 76 mm

-

Bicycle racks, railings, tree guards, bollards, etc. with a tube diameter of 48, 60 or 76 mm can be placed in these ground shells. The inserted tube is firmly fixed with screws and a locking ring. The removal by unauthorized persons is almost impossible. The disadvantage compared to 3p-Technology is the lack of a predetermined breaking point.

Bicycle racks, railings, tree guards, bollards, etc. with a tube diameter of 48, 60 or 76 mm can be placed in these ground shells. The inserted tube is firmly fixed with screws and a locking ring. The removal by unauthorized persons is almost impossible. The disadvantage compared to 3p-Technology is the lack of a predetermined breaking point.

View Product

Products with this Mounting Type:

Back to the overview. -

-

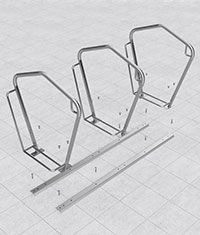

Trapezoidal rails for dowelling

-

Bicycle stand rows on trapezoidal rails for dowelling

We offer this type of fastening especially for bicycle stands (models 450-1, 452, 473, 480 et al.). It allows the modular assembly of row units with fixed wheel bases that can be connected as needed by means of series connectors.

Row units on trapezoidal rails provide a secure stand due to their length and allow an anti-theft anchoring to the ground. Since the racks are not welded but screwed onto the rails, their transport is easier and more cost-effective. In addition, individual racks can be removed and replaced in the event of damage.

Upon request, the length of the main racks can be increased so that the construction can be dowelled or set in concrete underground.

Products with this Mounting Type:

Back to the overview. -

PERSONAL ADVICE

ABES S. à r. l.

Parc d’Activité Syrdall 48, rue Gabriel Lippmann L-6947 Niederanven FON +352.28 67 65 01 FAX +352.28 67 65 20 shop@abes-online.com