3p-Technology

unrivaled.economical. trusted.

3p-Technology: The cost saving mounting system with pre-determined breaking point.

What is 3p-Technology

Crooked and knocked down bollards

Crooked or broken bollards can be seen in every city. These pictures are certainly quite familiar. The exchange of conventional bollards is laborious, it takes a lot of manpower and time. This always results in very high costs.

Bollard with 3p-Technology

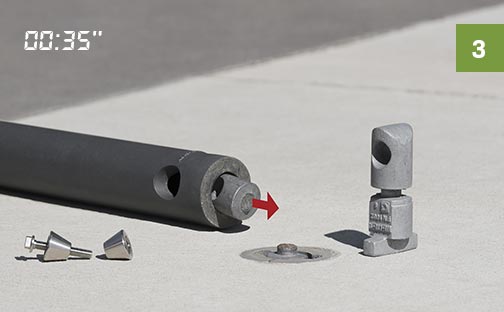

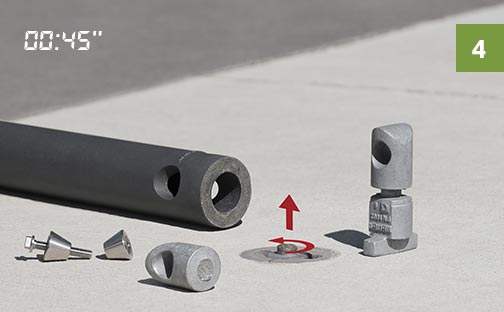

Our 3p-Technology is the solution. If a bollard was hit by a vehicle, the junction piece breaks at pre-determined breaking point.

Cost comparison

Enter your repair costs and compare.

Enter a few details and find out how much you save with the 3p-Technology.

compare!You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationWhat are the advantages?

Cost advantages in case of damage

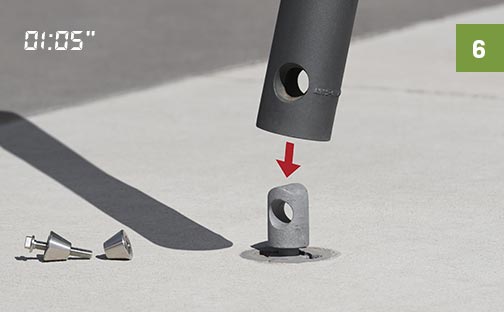

- ONLY EUR 35.00 for a replaceable junction piece with breaking point

- Less than 3 minutes working time

- Bollards, foundations with floor sleeves and plaster usually remain intact

- Costs reduced by up to 90 %

Mounting advantages

- Extremely sturdy system

- Fast replacement with simple tools

- Removable

Simplified Storage

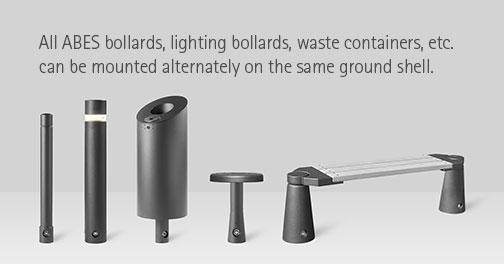

ONE ground shell for all products with 3p-Technology.

- Easy stockpiling

- Less storage space

- Low storage costs

Videos

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationBollards with 3p-Technology

For cities and communities, car parks and parking lots, airports and railway stations, universities and more, the 3p-Technology is the best system currently available.

More videosFunction

Bollard hit by a car.

The exchangeable junction piece breaks at the pre-determined breaking point. All parts including the foundation and paving remain undamaged. The broken junction piece is replaced by a new one. The bollard can be remounted immediately.

Flexibility

Removing bollards to create an open space

All bollards (and other products) with 3p-Technology are removable.This allows for the temporary creation of additional spacefor events, meetings, markets or parking lots. To prevent tripping or pollution,the ground shells can be closed with a cover.

Parc d’Activité Syrdall 48, rue Gabriel Lippmann L-6947 Niederanven FON +352.28 67 65 01 FAX +352.28 67 65 20 shop@abes-online.com